Be ready.

Think circular.

95% post

consumer

waste

100% post

industrial

waste

100% post

industrial

waste

The Blue Tube

uses 100% post-industrial product waste, which is recycled and reused for tube production.

95% post

consumer

waste

The Blue Tube Evo

uses at least 95% product waste, which is recycled after being disposed of by end consumers.

Key benefits of

the Blue Tube

products

Circular Economy

Retaining value that lasts

While other recyclable materials decline in quality after each lifecycle, aluminium retains all of its outstanding properties. Aluminium can easily be separated from other waste, and the necessary infrastructure is already widely in place. The products of the Blue Tube range are perfectly designed to fulfil legislative requirements and consumer preferences. They close the product-to-product loop by bringing aluminium product waste back into tube production.

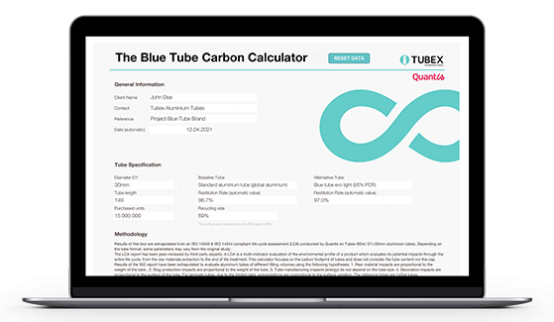

Calculate how much CO2 you can save with the Blue Tube brand

GET YOURCALCULATION NOW